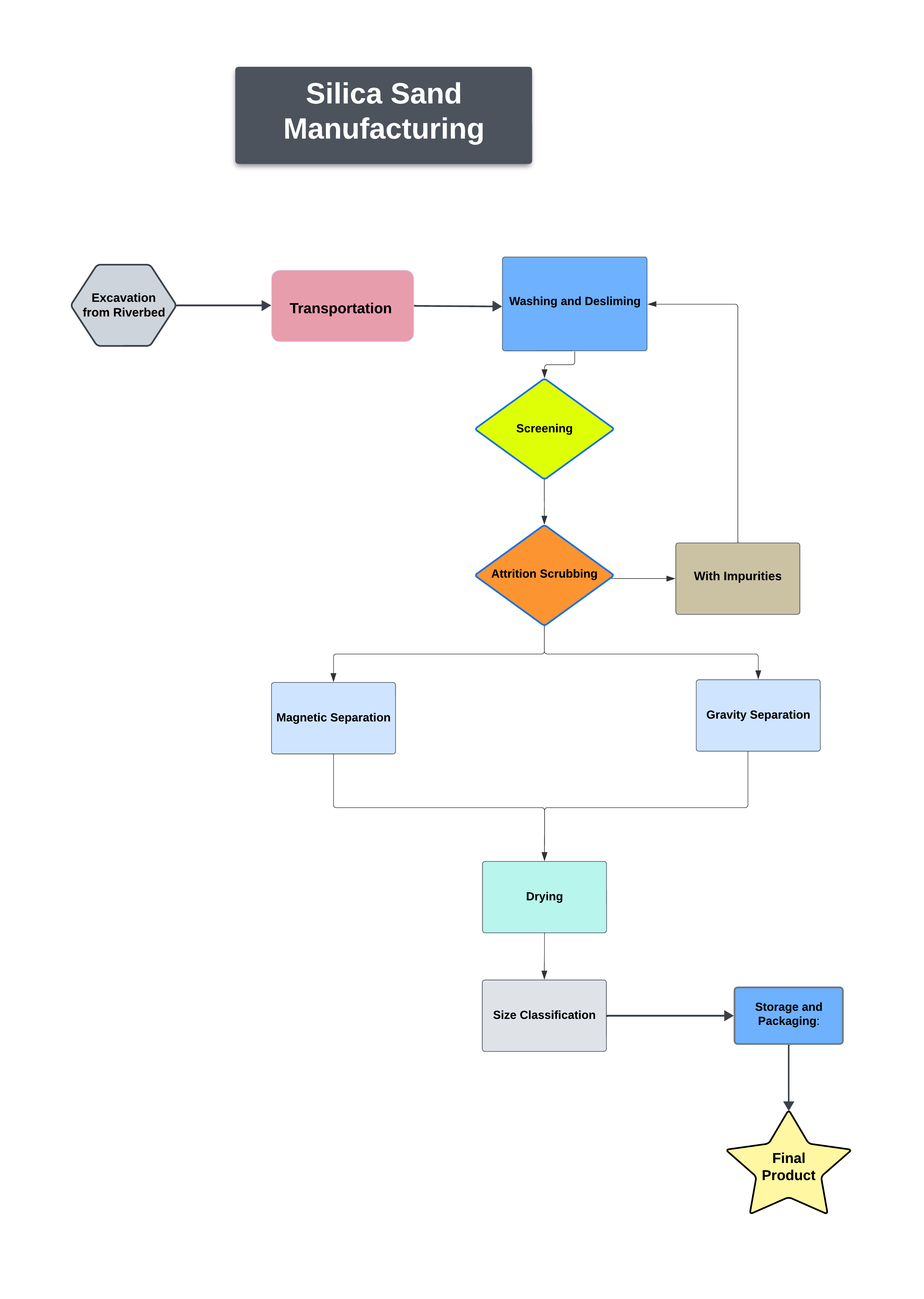

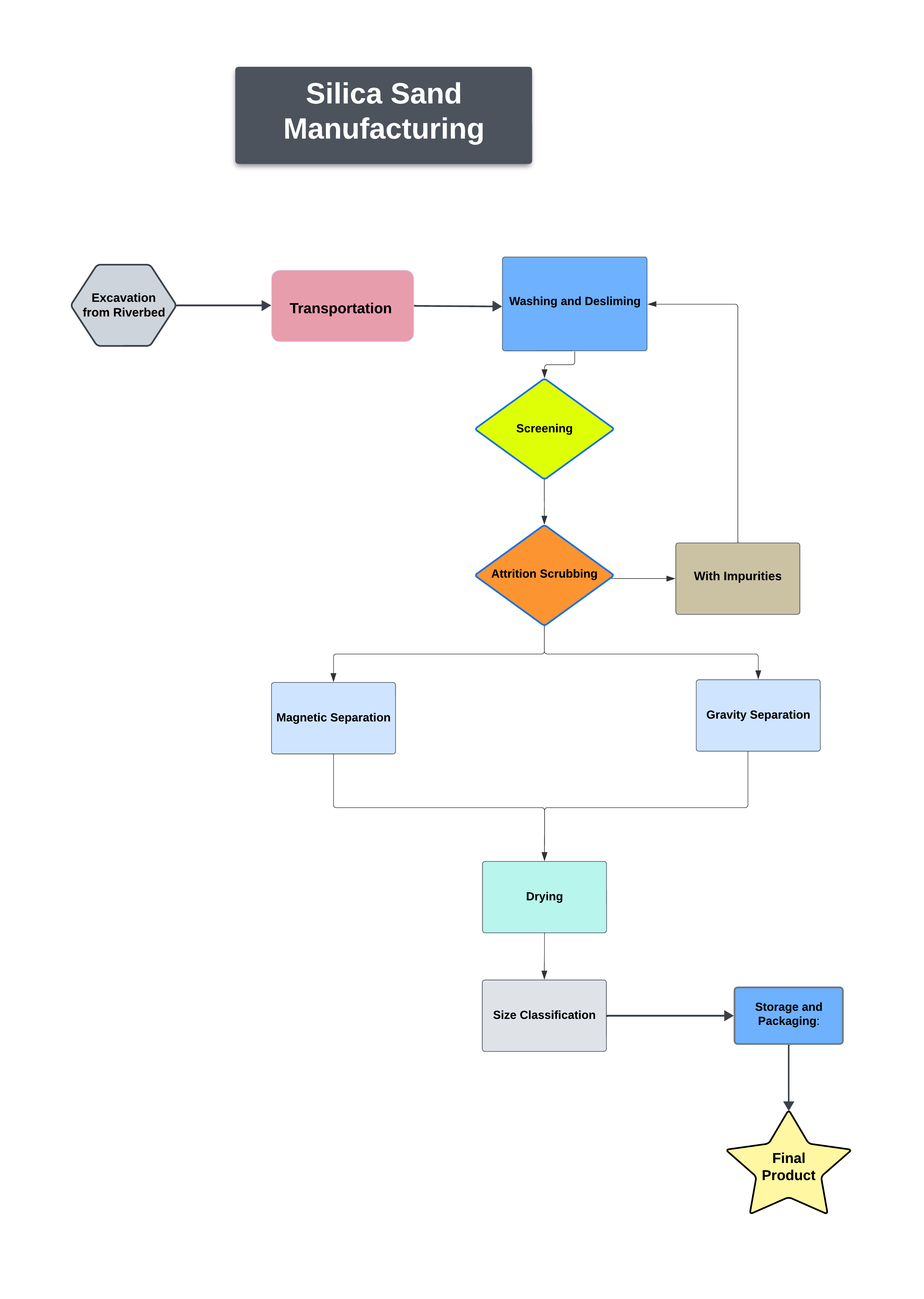

Our Products

We are a quality producer of washed and graded Foundry Grade Silica Sand and construction Grade Silica Sand.

Some of our product in below.

We are a quality producer of washed and graded Foundry Grade Silica Sand and construction Grade Silica Sand.

Some of our product in below.